Herr Engineering F4U Corsair Conversion

(lots of pictures so be patient)

The Herr Engineering

F4U-1 Corsair is a free flight rubber band kit that I converted to RC. I've

always had a love for the bent wing war bird, and after my successful

conversion of the 30" Dumas Bearcat I was looking for a new project. Just like the Bearcat, my goal was to utilize the latest micro

servos from Hitec or GWS (5~6 grams each), micro GWS 4 channel receiver (~4.5

gram), micro GWS 2-amp speed control (~1 gram), GWS IPS-A (Gear ratio: 5.86)

gearbox/motor combination, and a lightweight battery pack (< 2.25 oz). With these components and building the

structure reasonably light, my objective was to end up with a plane that

weighed less than 9.5 oz.

I originally wanted to include the GWS retracts for this conversion, but after

seeing the construction of the Corsair kit I changed my mind. Herr Engineering

uses harder balsa 3/32" stringers as opposed to the Dumas kits, which use

a softer 1/16" stringer. My point is that the Herr kits are built a little

heavier, but shouldn't be too heavy to include all the control surfaces.

For those wondering, I've done some calculations and came up with a wing

planform area around 166 sq. in. The Bearcat has about 170, so I was convinced

if everything went as planned I would end up with a fairly low wing loading.

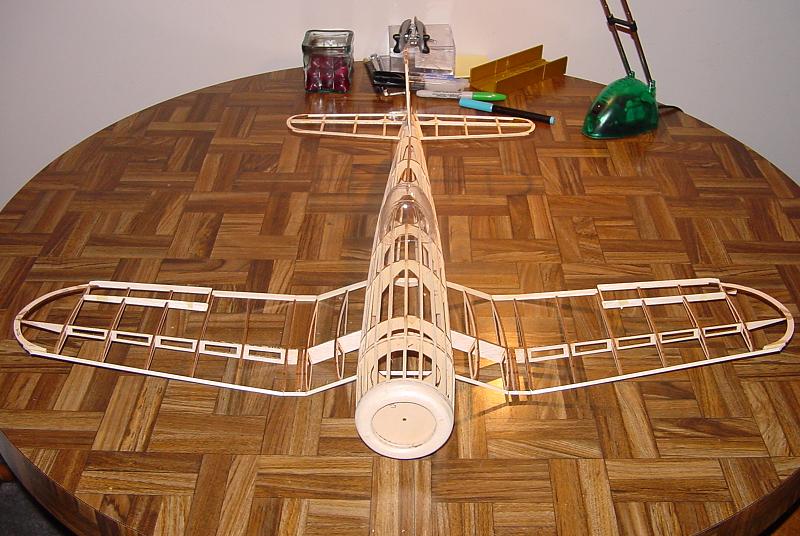

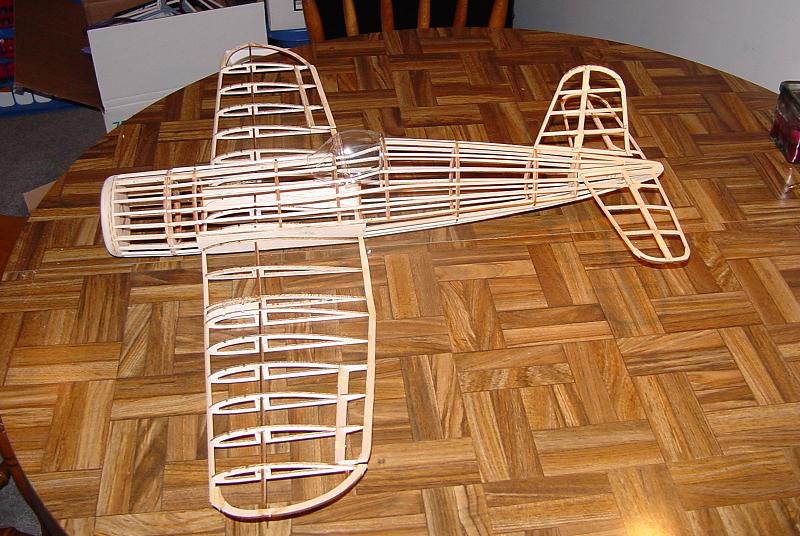

At this point the Corsair is essentially built up

completely stock except for building the separate control surfaces. Since the original model is a free flight

rubber band powered model you have to add control surfaces. I sized the control surfaces based on the

scale outline of the full-scale Corsair’s control surfaces and past model

building experience. Notice that the cowling is actually built up in the same

method as the fuselage. I've got it pinned to the fuselage in the pictures.

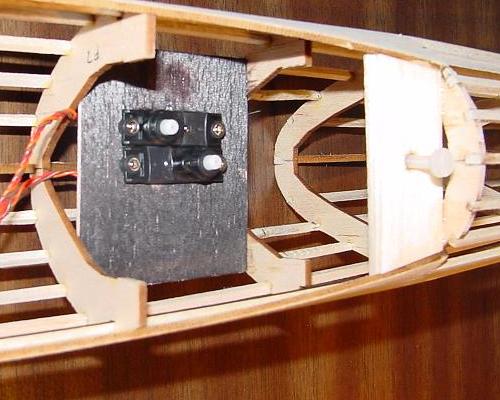

This picture shows how I “built” the DX-A out from the

original firewall of the stock model.

This was necessary to get the prop shaft to extend through the front of

the cowling.

The only reason the aileron servo is mounted where it is,

is so that it would be out of the way of the dowel that I have yet to install

in the wing. The dowel will run from the spar in the middle of the wing through

the leading edge. The front part of the wing will have a dowel that is mated

with a hole in the fuselage, and the back part of the wing will be held down with

a small nylon screw. It would actually be better to have less of a bending

radius in the flex cables, but regardless, it won't have enough friction to

hurt anything the way I have it setup either.

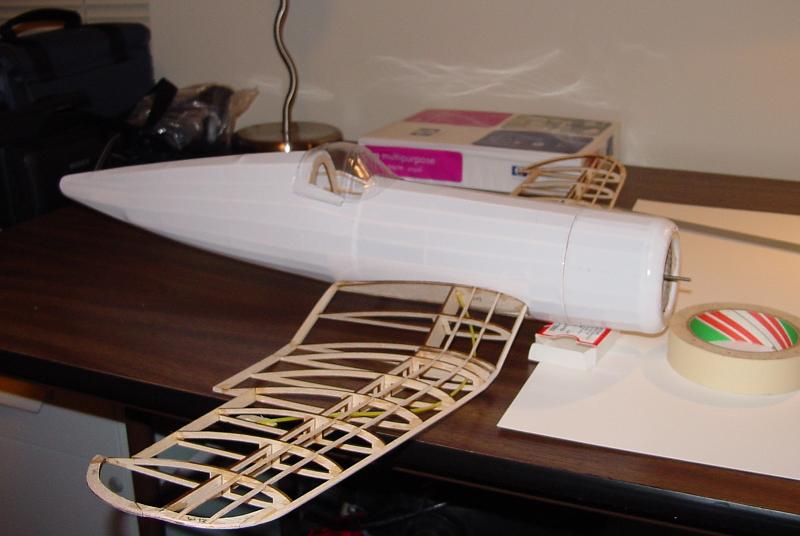

Here's a picture that shows the wing structure completed.

The wing has a 3/32" hardwood dowel in the front and a hole in the rear

for a 8-32 Nylon bolt to go through. The details of the aileron servo can be seen

as well.

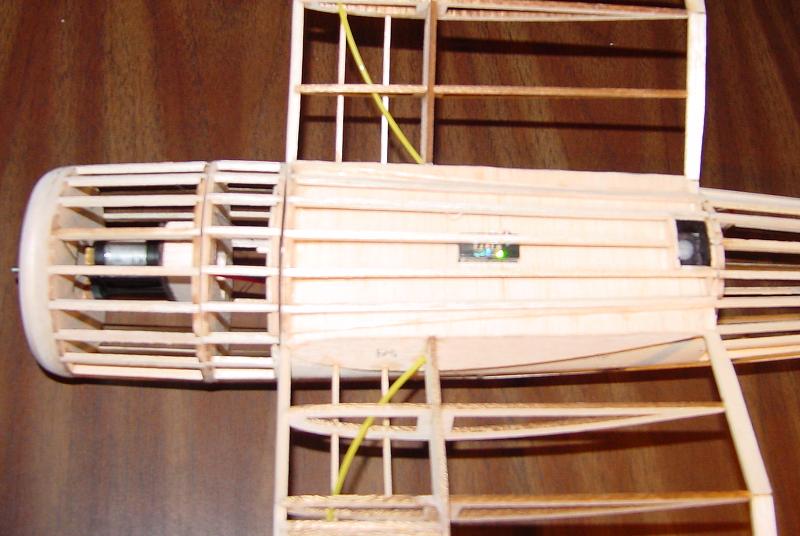

This picture shows the elevator and rudder servos mounted.

The space to the right of the servos is for the GWS receiver. You can see the Nylon

wing hold down bolt too.

This picture shows the wing bolted to the fuselage. The

Herr kit is very well put together, and the fuselage filler piece glue to the

bottom of the center of the wing fits really nice! Woohoo!

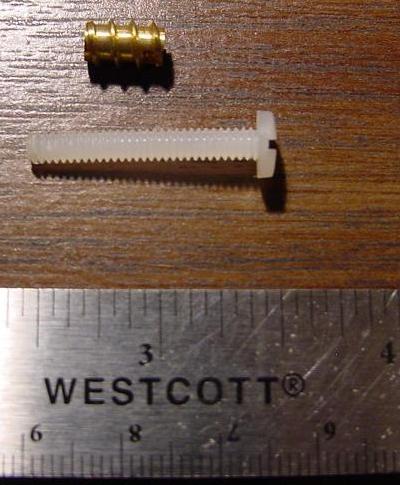

I thought I'd post a close up picture of the Nylon wing

bolt and small brass threaded insert. These little brass inserts work really

well. I've used this same system in my Bearcat, and the wing has not came off

yet. The wood block glued to the fuselage has to have a hole drilled to the

minor diameter of the outer brass insert thread, but no big deal. Just drill

the hole through the wing and through this block in the fuselage and the

alignment will be perfect every time. After I get the brass insert in the wood

block I hit it with some CA to keep it from working loose.

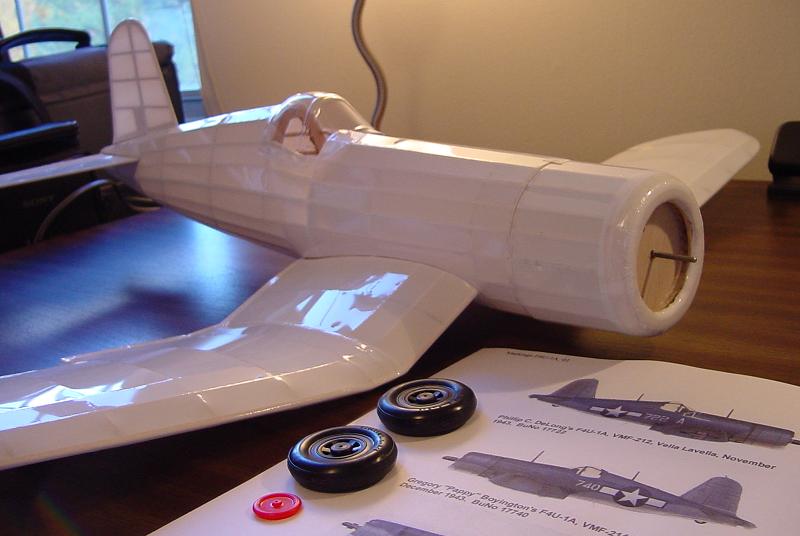

This picture shows the plane partially covered. I chose white Nelson Litefilm, AKA Solite

for the covering material (0.6 oz/sq. yd).

We’ll talk more about the paint scheme later.

The Corsair is completely covered and the wheels you see

are Guillow's wheels that I ordered from Dumas. The red one is for the tail wheel

and needs some paint really bad.

I don't have an airbrush so I got some 1/8" wide

plastic tape to do the irregular outline of the light blue sides of the

fuselage and got all that painted. Next I decided to tape all that I painted

the day before off so I could paint the dark blue portion of the plane. I

decided I would peel back a portion of the tape I just applied to see what

would happen and sure enough, the paint comes off with the tape. I even took

the time to rough up the covered plane with some synthetic steel wool to get

better paint adhesion. I cleaned the entire surface with a tack cloth and then

rubbing alcohol to get the surface nice and clean. Here is the problem, Solite

is flexible and Testors paint is not. When the tape was pulled off it would

flex the covering just enough to get the paint to release. So crap, what next

right? At this point I'm pretty damn frustrated, as this project is not turning

out so good. My only solution was to continue trying to make the Corsair look

"half-ass" decent with more paint, or strip all the white covering

off and recover it in all blue like my Bearcat. I decided to just go ahead and

see what I could do with what I have.

OK, well as disappointed as I was that this project didn't

completely go my way, I'm pretty satisfied with the results.

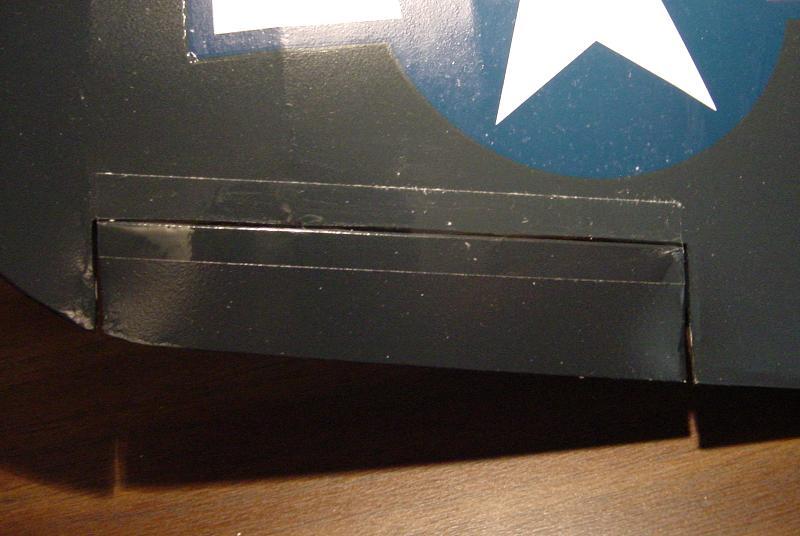

I use Scotch clear or magic tape for the hinges on all my

flight control surfaces. Haven't lost one yet do to tape failure, knock on

wood. knock knock.

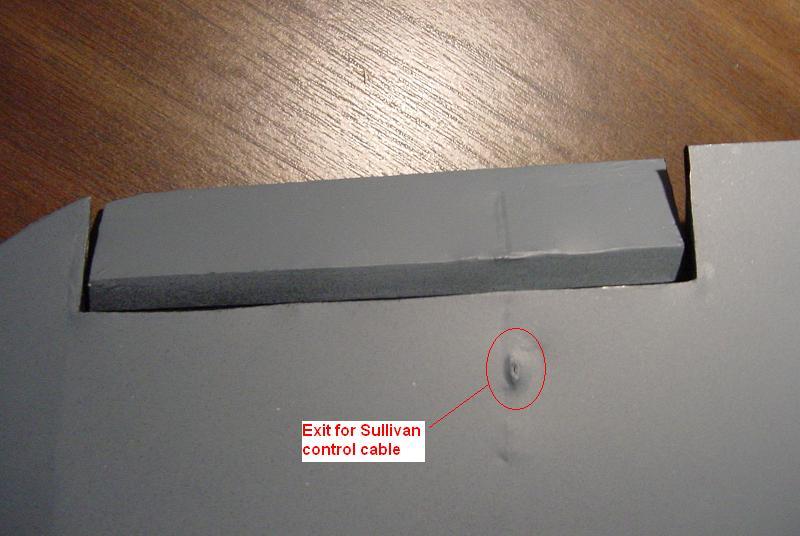

This picture shows the bottom of the aileron. You can see

the point where the cable will exit. Also, notice the chamfer on the bottom of

the front of the aileron. Make sure you have an angle that will allow the

aileron throw you desire. I build some

wood into the aileron so that I'll have something for the control horn to glue

to.

Success! This

picture was captured from my camcorder and shows how the tail elevated on take

off.

This picture was also captured from my camcorder and shows

the plane on one of its scale looking fly bys.

To see some video of the Corsair in action please take a look in the

parkflyer picture/video download section on www.silentflightonline.com. If you want you can also click the following

link to view it directly.

http://www.silentflightonline.com/Site/Members/ImageBase/Images/866.wmv